Main technical parameters:

1. Stainless steel precision filter element working temperature: ≤ 500 °C

2. Filtering precision: 1-200um

3. Working temperature: 0.1-30MPa

4. filter specifications: 5-40 inches (can be made according to user requirements)

5. Interface Form: Thread Interface, 222, 226, 220, etc.

Whatsapp:

+8613569807092E-mail:

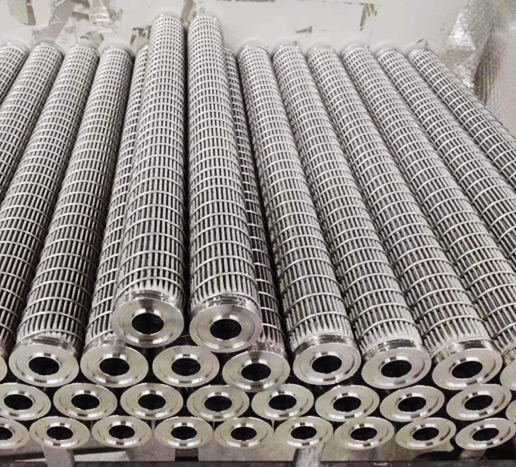

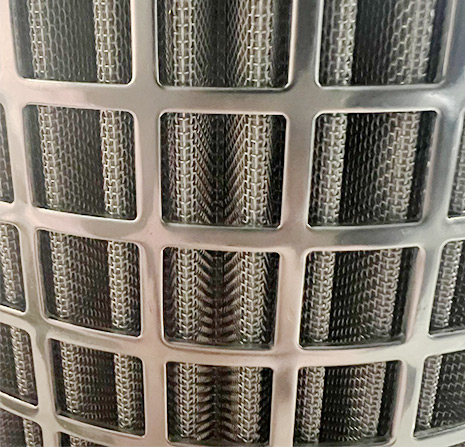

sales@world-filters.comStainless steel sintered filter element Main filter material adopts 304,304L, 316,316L stainless steel fiber sintered felt and stainless steel woven net as main filter media. Stainless steel fiber sintered felt is a kind of porous filter material made of stainless steel fibers by high temperature sintering. Stainless steel woven wire is woven from stainless steel wire.

Stainless steel precision filter element has high porosity, good permeability, small resistance and low pressure difference.

After the stainless steel precision filter element is folded, the filtering area is large and the pollution capacity is large.

Stainless steel precision filter element high temperature resistance, corrosion resistance, suitable for highly viscous liquid filtration;

Good regeneration performance, chemical cleaning, high temperature and ultrasonic cleaning can be used repeatedly;

All stainless steel structure, wide chemical compatibility;

Stainless Steel Folding Filter Cleaning Method:

1. In the production line generally choose backwash: first off the original liquid and filter liquid pipeline switch, Rinse with bacteria-free water, input from the original outlet, discharged from the inlet or the lower part of the filter discharge hole, backwash should have pressure but not too large, generally about 5 kg.

2. Remove the stainless steel folding filter element and put it in the cleaning solution. Soak it in repeated cleaning. Cleaning fluid is generally available:

A. Sodium hydroxide, 0.1 N NaOH

B. 1-2% citric acid water fluxes or 0.1 N oxalic acid solvent, 0.1 N. hydrochloric acid solvent.

C. enzyme solvent and other solvents when cleaning the general temperature control in 30-40 degrees is better.

Cleaning Notes: filter solution protein content is relatively high, such as draft beer, nutrient solution, etc., after cleaning the filter must be high-temperature disinfection, to prevent high temperature coagulation of protein clogging membrane hole.

Stainless Steel Folding Filter Element Mounting Method:

1. In the installation of plug-in filter should be first O-ring in clean water in the filtrate wet, in order to reduce the insertion of friction. And requirements inserted in the end, to ensure that the two O-ring have a sealing role.

2. To install the snap - in filter cartridge, you need to rotate clockwise.

3. If the filter has a pressure plate, press the pressure plate on the warped sheet and press the spring gently, if the spring is too tight, the space without elongation will be distorted and affect the filtering precision.

4. When filtering liquid, you should first open the exhaust switch on the shell, empty the gas in the filter cartridge, let the liquid fill the cartridge, otherwise it will affect the flow.

5. Fluid filter will have pressure drop because of resistance, in order to overcome the resistance must have enough working pressure in order not to make the filter by the impact of large flow, to open the valve slowly.

Thanks for your interest. To receive more product information, price, catalog, etc. Please fill out the form bellow. We will get back to you within 24 hours.

For more than 30 years, we have provided high quality filtration products to domestic and foreign customers, such as SS316L sintered fiber felts, SS316L multilayer wire mesh, SS312 sintered fiber felts, sintered special performated screen, sintered metal powder elements, and other sintered filter materials, filter elements and filtration equipment systems.